Safisana’s circular waste-to-resource model has proven its impact in Ashaiman: improving sanitation, generating clean energy, and supporting sustainable agriculture. Currently, we operate in Accra and Kumasi and aim to expand across Africa. To scale means we need to be able to predict how our production plants will perform under different local conditions. That's why we are proud to share that we have developed Safisana's own dynamic simulation model.

Before 2025, Safisana relied on static spreadsheet models to estimate impact and performance. While useful, these models could not account for real-world dynamics such as seasonal changes, varying waste input volumes, operational downtime, or phased expansion scenarios. As a result, they increased the risk of over- or undersizing facilities and made long-term scaling decisions less efficient.

To strengthen our business development and scaling ambitions, we needed a more advanced approach.

Engineering for Change

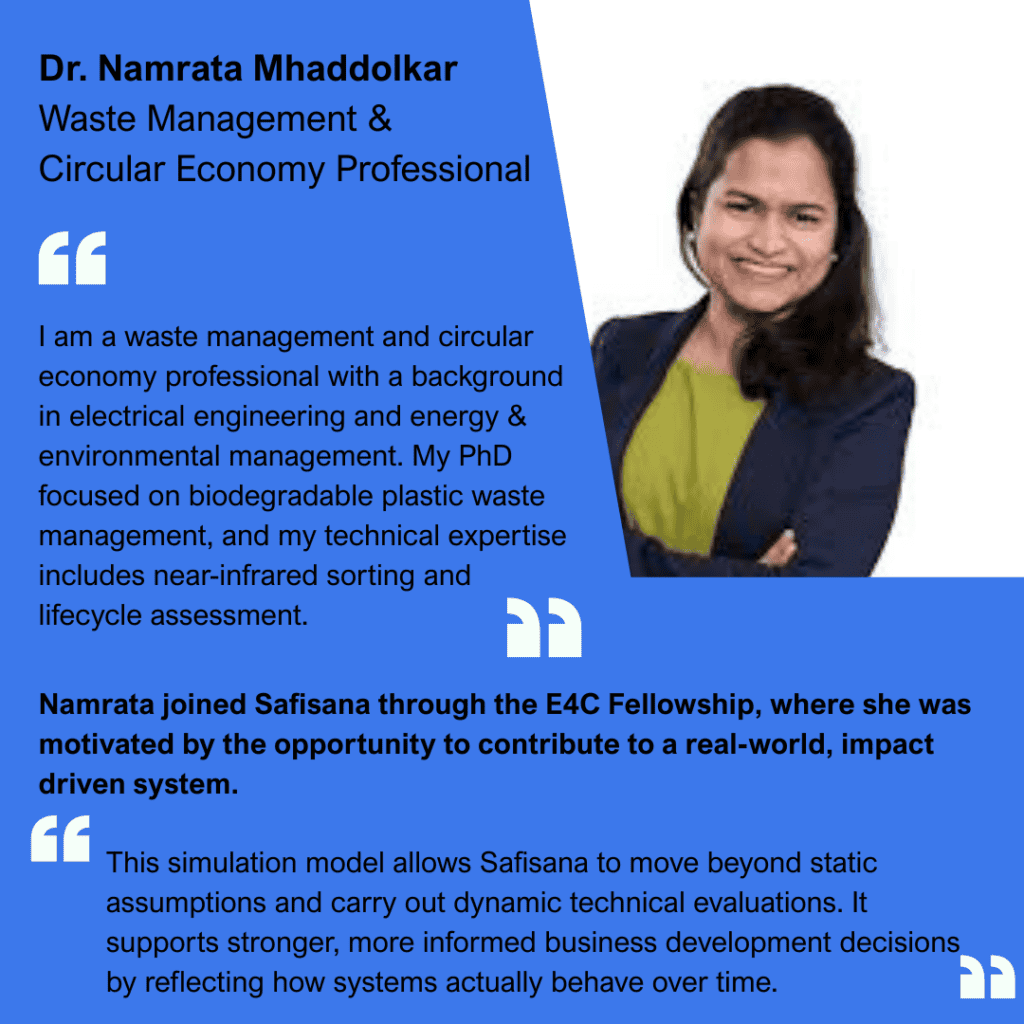

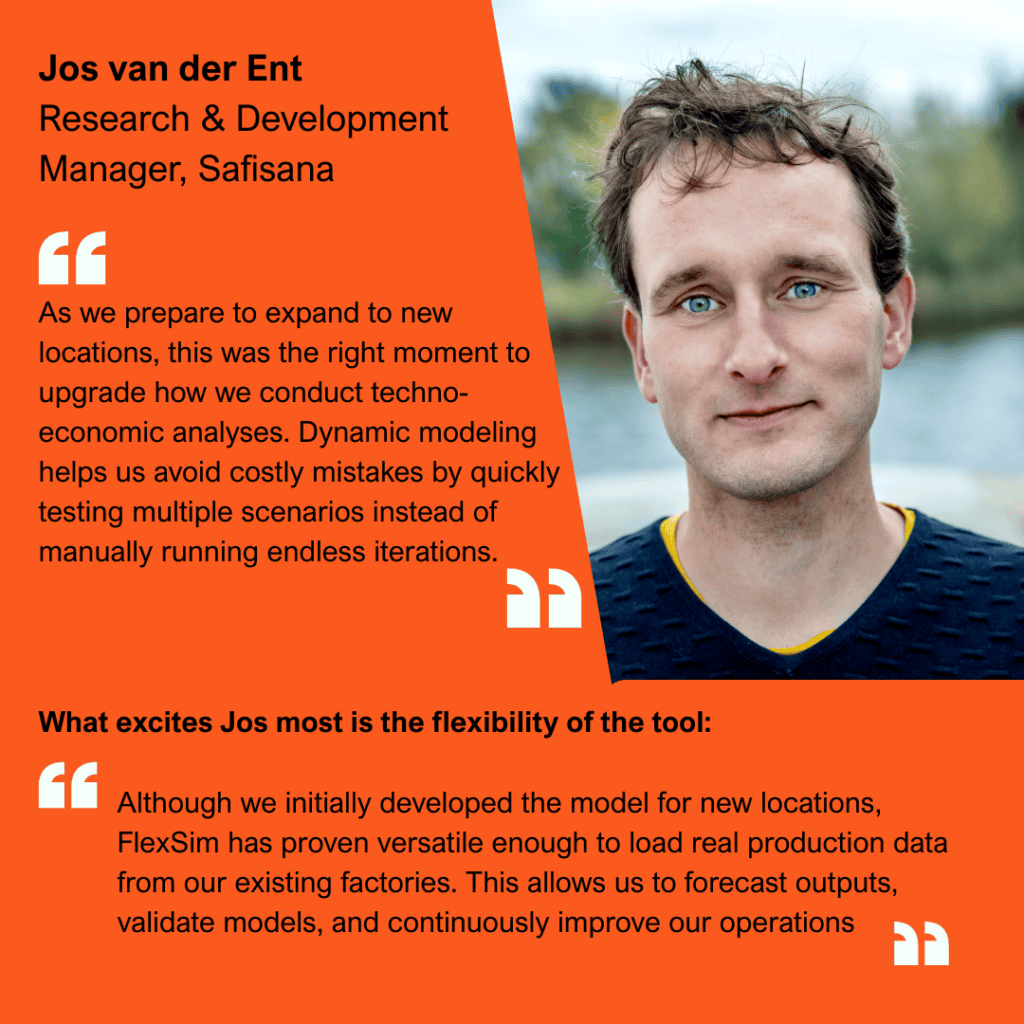

With support from our funder, Autodesk Foundation, Safisana joined the Engineering for Change fellowship program. Through this program, waste management researcher Dr. Namrata Mhaddolkar led the development of a variable simulation model, working closely with Jos van der Ent, Safisana’s Research and Development Manager.

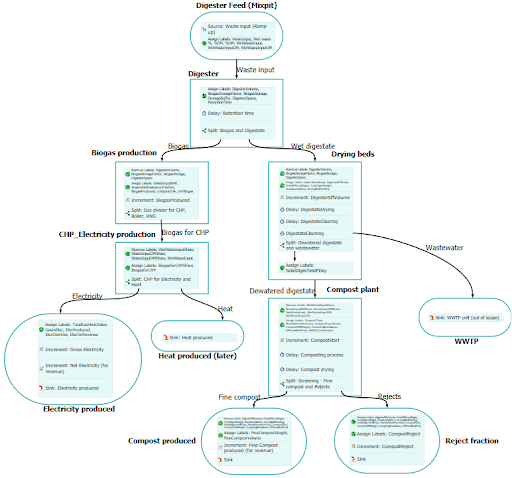

Using FlexSim and G-Suite software, the team built a dynamic simulation model that calculates waste flows, fertilizer and biogas production, and energy output. Unlike static spreadsheets, the model adjusts in real-time to changes in input volumes, seasonal patterns, operational efficiency, and location-specific parameters.

A Simulation Model for Improved Efficiency

With this model, we can now test scenarios and make informed, data-driven decisions before investing in new locations. Overall, the dynamic model reduces risks and strengthens our business decisions moving forward.

The model also enhances our commercial and social viability by demonstrating efficiency, reducing emissions, and showcasing revenue potential. The model is not only useful for new operations, but it also benefits us in predicting the impact of our existing plants. We can now test process changes before implementing them. This is especially useful with seasonal changes that may impact our production flow and when planning operational upgrades.

Building future-ready sanitation systems

This new simulation model significantly strengthens Safisana’s ability to scale its circular sanitation solution to more communities in non-sewered urban areas. By better understanding real-world conditions before construction, we reduce risk, improve planning, and accelerate our path to impact.

As Safisana grows, dynamic modeling will play a crucial role in ensuring that every new plant is financially viable, socially impactful, and technically replicable.

- A Simulation Model that Powers Safisana’s Growth

- Teaching the Next Generation that “Your Poop is Power”

- World Toilet Day 2025: Why it Matters in Ghana & Why it Matters to Safisana

- How Safisana Transforms Waste into Clean Energy and Organic Fertilizer

- Safisana Recognized as Exemplary Bioeconomy Solution by the Netherlands Agricultural Network